Introduction:

A

defect in the knitted fabric is an abnormality, which spoils the aesthetics

i.e. the clean & uniform appearance of the fabric & effects the

performance parameters, like; dimensional stability etc.

There

are various types of defects, which occur in the Knitted fabrics of all types,

caused by a variety of reasons. The same type of defects may occur in the

fabric, due to a variety of different causes e.g. Drop Stitches, Spirality. Prime

causes of the fabric defects are, as follows;

·

Yarns

·

Knitting

Elements

·

Knitting

Machine Settings

·

Dyeing

·

Finishing

v Types of Defects:

·

Drop

Stitches or Holes

·

Barriness

·

Streakiness

·

Imperfections

·

Snarling

·

Contaminations

·

Spirality

·

Needle

Lines

·

Broken

Needles

·

Sinker

Lines

·

Oil

Lines or Stains

·

Broken

or Missing Ends

·

Fabric

Press Off

·

Surface

Hairiness & Piling

·

Snagging

·

Bowing

·

Dyeing

Patches

·

Softener

Marks

·

Stains

·

Color

Fading

·

Shade

Variation

·

Tonal

Variation

·

Wet

Squeezer Marks

·

Fold

Marks

·

Crease

or Rope Marks

·

Skewing

or Diagonal Grain Lines

·

Shrinkage

·

GSM

Variation

·

Width

Variation

·

Curling

of Edges

·

Measurements

Category

of Defects:

Yarn related defects

Almost

all the defects appearing

in the horizontal direction,

in the knitted fabric are, yarn related. These defects are mainly;

·

Barriness

·

Thick

& Thin lines

- Dark

or Light horizontal lines

(due

to the difference in dye pick up)

- Imperfections

- Contaminations

- Snarling

- Spirality

Knitting Elements related defects

Almost

all the defects appearing

in the vertical direction,

in the knitted fabrics, are as a cause of bad Knitting Elements. These defects

are mainly;

·

Needle

& Sinker Lines

Machine Settings related Defects

These

defects appear randomly in the knitted fabrics, due to the wrong knitting machine

settings & that of the machine parts. The defects are mainly;

·

Drop

Stitches

·

Yarn

Streaks

·

Barriness

·

Fabric

press off

·

Broken

Ends

·

Spirality

Dyeing related defects

The

Dyeing related defects are, as follows;

·

Dyeing

patches, Softener Marks

·

Shade

variation

·

Tonal

variation

·

Color

fading (Poor Color Fastness)

·

Dull

shade

·

Crease

or rope Marks

Finishing related defects

Defects

caused, mainly due to the wrong process parameters are;

·

High

Shrinkage

·

Skewing

·

Spirality

·

Surface

Hairiness & Pilling

·

Tonal

variation

·

Snagging

(Sharp points in the dyeing machine or trolley etc)

·

Fold

Marks

·

Wet

Squeezer Marks

·

GSM

variation

·

Fabric

Width variation

Drop Stitches (Holes)

Definition:

Drop

Stitches are randomly appearing small or big holes of the, same or different

size, which appear as defects, in the Knitted fabrics.

Major Causes:

- Yarn Overfeed or Underfeed

- High Fabric Take Down Tension

- Obstructions in the yarn passage, due to the

clogging of eyelets, yarn guides & tension discs, with wax & fluff

etc.

- Defects like; Slubs, Neps, Knots etc.

- Incorrect gap between the Dial & Cylinder

rings.

Remedies:

- Ensure uniform yarn tension on all the feeders,

with a Tension Meter.

- Rate of yarn feed should be strictly regulated,

as per the required Stitch Length.

- The fabric tube should be just like a fully

inflated balloon, not too tight or too slack.

- Eyelets & the Yarn Guides, should not have,

any fibers, fluff & wax etc. stuck in them.

- The yarn being used, should have no

imperfections, like; Slubs, Neps & big knots etc

- The gap between the Cylinder & the Dial

should, be correctly adjusted, as per the knitted loop size.

Barriness

Definition:

Barriness defect appears in the Knitted fabric, in

the form of horizontal stripes of uniform or variable width.

Causes:

- Package hardness variation

Remedies:

- Ensure uniform Yarn Tension on all the feeders.

- The average Count variation in the lot, should

not be more than + 0.3

- Ensure that the yarn being used for Knitting is

of the same Lot / Merge no.

- Ensure that the hardness of, all the yarn

packages, is uniform, using a hardness tester.

Streakiness

Definition:

Streaks

in the Knitted fabrics appear as; feeble,

irregularly spaced & sized, thin horizontal lines.

Causes:

- Yarn slippage on the IRO Pulley, due to the

yarn slipping in & out from underneath the IRO Belt, due to a tilted

IRO Pulley.

- Worn out IRO belts, yarn guides & eyelets

etc

- Faulty winding of the yarn packages

- Yarn running out of the belt, on the IRO Pulley

Remedies:

- Ensure very smooth, clean & obstruction

free passage of the yarn, through the eyelets, yarn & tension discs

etc.

- No cuts or rough surfaces, in the Porcelain

Eyelets, Yarn Guides & the Yarn Feeder holes etc.

- Flawless winding of the, Yarn Package (The yarn

coils should unwind smoothly, without any obstruction)

- The yarn should be running under the IRO belt,

between the belt & around the IRO pulley

Imperfections

Definition:

Imperfections appear on the fabric surface, in the

form of unevenly placed or randomly appearing, Knots, Slubs & Neps, Thick

& Thin places in the yarn.

Causes:

- Big Knots, Slubs & Neps in the yarn, Thick

& Thin yarn (Uneven USTER)

Remedies:

- Specify the quality parameters of the yarns, to

be used for production, to the yarn supplier.

- Specify the number of acceptable Imperfections

/ Km. of the yarn & the USTER evenness %, while ordering the yarn.

Snarls

Definition:

Snarls appear on the fabric surface, in the form of

big loops of yarn getting twisted, due to the high twist in the yarn

(Unbalanced twist yarn).

Causes:

- High, twist in the, yarn.

- Hosiery yarns are soft twisted. High, twist in

the yarn, is the cause of snarling.

- (Snarls cause, fabric defects & needle

breakages)

Remedies:

- Ensure using Hosiery Yarns, of the recommended

T.P.M. only.

- (Hold a few inches of the yarn in both the hands,

in the form of a ‘U’.

- The yarn has a balanced twist, if it doesn’t

tend to rotate or turn, in the form of a snarl.

- (Such yarn can be used for Hosiery

applications.)

Contaminations

Definition:

Contaminations appear, in the form of foreign

matter, such as; dyed fibers, husk, dead fibers etc., in the staple spun

yarn or embedded in the knitted fabric structure.

Causes:

- Presence of dead fibers & other foreign

materials, such as; dyed fibers, husk & synthetic fibers etc.

- Dead Fibers appear in the fabric, as a result

of the, presence of excessive immature Cotton fibers, in the Cotton fiber

crop.

- Dead fibers do not pick up color during Dyeing.

- Presence of the foreign materials, in the,

staple fiber mixing

- (Kitty, Husk, Broken Seeds, dyed fibers &

fibers like Poly Propylene, Polyester, Viscose etc)

- Dyed & other types of fibers flying from

the adjacent Knitting machines cling, to the yarn being used for knitting

& get, embedded in the Grey Fabric.

Remedies:

- Use rich fiber mixing for the yarns, to be used

for Knitting, in order to have less dead fibers, appearing in the fabric.

- Rigid control measures in the Blow Room, to

prevent the mixing of foreign matters in the Cotton mixing.

- Segregate the Spinning & Knitting Machines,

with Plastic Curtains or Mosquito Nets, to prevent the fibers flying from

the neighboring machines, from getting embedded in the yarn / fabric.

Spirality

Definition:

Spirality appears in the form of a twisted garment,

after washing. The seams on both the sides of the garment displace, from their

position & appear on the front & back of the garment.

Causes:

High T.P.M. of the Hosiery Yarn

- (Spirality is caused, by the Twisting Torque as

a result, of the high yarn T.P.M.)

- (Hosiery yarns are soft twisted, whereas the

Warp yarns are hard twisted)

- Uneven Fabric Take down tension, on the Knitting

machine.

- Unequal rate of Fabric feed on the Stenter,

Calender & Compactor machines.

Remedies:

- Use the Hosiery yarns of the recommended TPM

level for Knitting

- (Hosiery yarns are soft twisted, in comparison

to the Warp yarns)

- Fabric pull or the Take Down tension, on both

sides of the grey fabric tube, on the knitting machine, should be

equal.

- Ensure uniform rate of feed of the dyed fabric,

on both the edges, while feeding the fabric to the Calander, Compactor or

Stenter machines.

Needle Lines

Definition:

Needle lines are prominent, vertical lines, along

the length of the fabric, which are easily visible in the grey as well as

finished fabric.

Causes:

- Bent Latches, Needle Hooks & Needle stems

- Tight Needles in the grooves

- Wrong Needle selection (Wrong sequence of

needles, put in the Cylinder or Dial)

Remedies:

- Inspect the grey fabric on the knitting machine

for any Needle lines.

- Replace all the defective needles having, bent

latches, hooks or stems.

- Remove the fibers accumulated in, the Needle

tricks (grooves).

- Replace any bent Needles, running tight in the

tricks.

- Check the Needle filling sequence in the

Cylinder / Dial grooves (tricks).

Broken Needles

Definition:

Defects

caused by the broken needles, show prominently, as vertical lines parallel to

the Wales.

There are no loops formed in the Wale, which has a broken needle.

Causes:

- Bad Setting of the Yarn Feeders

- Old & Worn out Needle set

Remedies:

- Ensure uniform & the right Yarn tension on

all the feeders.

- Keep the recommended gap, between the Yarn

Feeders & the Needles.

- Periodically change the complete set of needles.

Sinker Lines

Definitions

Sinker lines are prominent or feeble vertical lines,

appearing parallel to the Wales,

along the length of the knitted fabric tube.

Causes:

- Sinkers being tight in, the Sinker Ring grooves

Remedies:

- Replace, all the worn out or bent sinkers,

causing Sinker lines in the fabric.

- Sinker lines are very fine & feeble

vertical lines, appearing in the fabric.

- Remove the fibers, clogging the Sinker tricks

(Grooves)

Oil Lines

Definitions:

Oil lines are prominent vertical lines, which appear

along the length of the knitted fabric tube. The lines become permanent, if the

needle oil used is not washable & gets baked, due to the heat, during the

finishing of the fabric.

Causes:

- Fibers & fluff accumulated in the needle

tricks, which remain soaked with oil.

- Excessive oiling of the, needle beds.

Remedies:

- Fibers, accumulated in the needle tricks, cause

the oil to seep into the Fabric.

- Some lubricating oils are not washable & can

not be removed during Scouring.

- Oil lines appear in the fabric, in the

lengthwise direction, even after dyeing.

- Remove all the Needles & the Sinkers of the

machine, periodically.

- Clean the grooves of the Cylinder & Dial of

the machine thoroughly, with petrol.

·

Blow the grooves of the Cylinder, Dial & Sinker

ring, with dry air after cleaning.

Broken Ends

Definition:

Broken ends appear as equidistant, prominent

horizontal lines, along the width of the fabric tube, when a yarn breaks or is

exhausted.

Causes:

- Yarn exhausted on the Cones.

Remedies:

- Ensure correct yarn tension on all the feeders.

- Ensure that the Yarn detectors on all the

feeders are working properly.

- Depute a skilled & alert machine operator,

on the knitting machine.

Fabric Press Off

Definition:

Fabric press off appears, as a big or small hole in

the fabric, caused due to the interruption of the, loop forming process, as a

result of the yarn breakage, or closed needle hooks.

Press off takes place, when the yarn feeding to both

the short butt & long butt needles, suddenly stops, due to the yarn

breakage.

At times, complete fabric tube can fall off the

needles, if the needle detectors are not functioning, or are not properly set.

Causes:

- End breakage on feeders, with all needles

knitting.

- Yarn feeder remaining in lifted up position,

due to which, the yarn doesn’t get fed in the hooks of the needles.

Remedies:

- Needle detectors, should be set precisely, to

detect the closed needles & prevent the fabric tube from completely

pressing off.

- Proper yarn tension should be maintained, on

all the feeders.

Surface Hairiness & Piling

Definition:

Surface hairiness appears in the form of excess

superfluous fibers, on the surface of the knitted fabrics, which have either

been reprocessed, or tumble dried.

Pilling appears as, small fiber balls formed on the

fabric surface, due to the entanglement of loose surface fibers.

Factors such as, the fiber staple length, low T.P.M.

& fabric construction (with long yarn floats) etc. also contribute to

pilling.

Causes:

- Abrasion due to the contact with rough surfaces

- Excessive surface hairiness caused, due to the

abrasive tumbling action

- (Fabric friction in the Tumble Dryer)

- Rough Dyeing process & abrasive machine

surfaces (Soft Flow Machine tubes, Tumble Dryer drum etc.)

- Reprocessing of the fabric is, also a major

cause of piling.

Remedies:

- Avoid using the Tumble Dryer.

- (Control shrinkage by maximum fabric relaxation

& over feed in the processing)

- Regularly inspect the fabric contact points on

all the machines, for any rough & sharp surfaces.

- (Rectify, if found rough)

- Avoid repeated reprocessing of the fabrics.

- Use anti pilling chemical treatments for the

fabrics, prone to pilling.

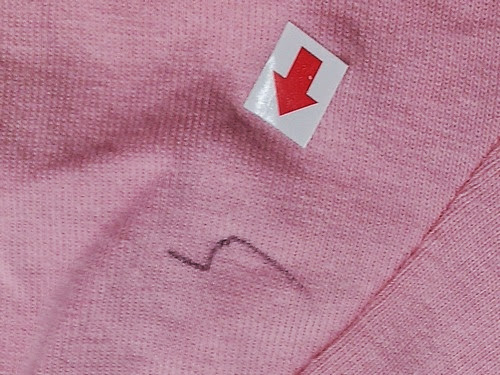

Snagging

Definition:

Snagging appears on the knitted fabric surface, as a

pulled up yarn float, showing up in the form of a large loop.

Causes:

- Caused by the pulling or the plucking of yarn

from the, fabric surface, by sharp objects.

Remedies:

- Inspect & rectify the fabric contact points

on all the machines (Soft Flow Dyeing, Tumble Dryer & Centrifuge etc),

on which snagging is taking place.

Bowing

Definition:

Bowing appears as, rows of courses or yarn dyed

stripes, forming a bow shape, along the fabric width.

Causes:

- Uneven distribution of tensions, across the

fabric width while, dyeing or finishing the fabric.

Remedies:

- Bowing can be corrected, by reprocessing the

fabric, by feeding it from the opposite end.

- A special machine (MAHLO) is also available

for, correcting the bowing in the knitted fabrics.

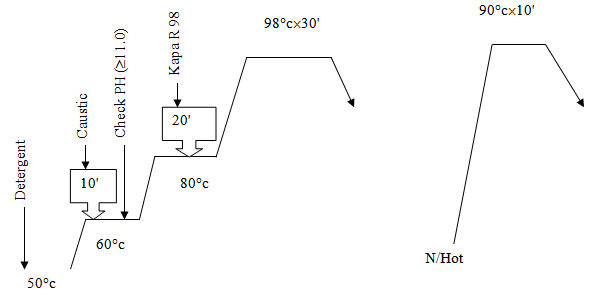

Dyeing Patches

Definition:

Dyeing patches appear, as random irregular patches

on the surface of dyed fabrics.

Causes:

- (Scouring, Dyeing recipe, Dyeing Machine

stoppage, Softener)

- Inadequate Scouring of the grey fabric is one

of the primary causes of the dyeing patches.

- Improper leveling agent is also one of the

causes of dyeing patches.

- Correct pH value not maintained.

- Dyeing machine stoppage, due to power failure,

or the fabric entanglement, in the, dyeing machine are, a major cause of

the dyeing patches.

Remedies:

- Scour the grey fabric thoroughly, to remove all

the impurities from the fabric, before dyeing.

- Use appropriate leveling agents, to prevent

patchy dyeing.

- Maintain the correct pH value, during the

course of dyeing.

- Use a power back up (Inverter) for the dyeing

operation to be completed, uninterrupted.

Softener Marks

Definition:

Softener marks appear as distinct irregular patches

in the dried fabric, after the application of softener.

Causes:

- Softener not being uniformly dissolved in water

Remedies:

- Scour the grey fabric thoroughly, to remove all

the impurities from the fabric, before dyeing.

- Ensure that the softener is uniformly dissolved

in the water & doesn’t remain un-dissolved as, lumps or suspension.

- Use the right softener & the correct

procedure for the application.

- Maintain the correct pH value of the softener,

before application.

Stains

Definition:

Stains appear as spots or patches of grease, oil or

dyes of different color, in a neat & clean finished fabric surface.

Causes:

- Dyeing Machine not cleaned thoroughly, after

dyeing a lot.

- Grease & Oil stains from the unguarded

moving machine parts, like; Gears, Shafts, Driving Pulleys &

Trolley wheels etc.

- Fabric touching the floors & other soiled

places, during transportation, in the trolleys.

- Handling of the fabric, with soiled hands &

stepping onto the stored fabric with dirty feet or shoes on.

Remedies:

- Wash & clean the dyeing machine thoroughly,

after dyeing every dye lot.

- Follow the dyeing cycle of Light- Medium-

Dark shades & then the reverse the cycle, while dyeing the fabric.

- All the lubricated moving machine parts, should

be protected, with safety guards

- Make sure that the fabric is neatly packed in

or covered with Polythene sheets, while transporting or in storage.

- Handle the fabric carefully, with clean hands

& do not let anyone step onto the stored fabric.

Color Fading (Poor Color Fastness)

Definition:

The color of the garment or the fabric appears,

lighter & pale, in comparison to the original color of the product, after a

few uses.

Causes:

- (Washing, Crocking, Chlorine, Light, Perspiration)

- Dyeing recipe i.e. the poor fixing of the dyes

is a major cause, of color fading.

- Using the wrong combination of colors in a,

secondary or tertiary shade.

- Use of strong detergents & the quality of

water are also the common causes for color fading.

- Prolonged exposure to strong light will, also

cause the colors to fade.

- High level of acidity or alkalinity in the

perspiration of individuals also, causes color fading.

Remedies:

- Use the correct dyeing recipe i.e. the

appropriate leveling, fixing agents & the correct combination of dyes.

- Follow the wash care instructions rigidly.

- Use mild detergents & soft water for

washing the garments.

- Don’t soak the garments for more than 10- 15

minutes, in the detergent, prior to washing

- Turn the wet garments, inside out, while

drying.

- Dry in shade & not in direct sunlight

- Protect the garments against prolonged direct

exposure to strong lights (show rooms or exhibitions etc.).

Shade variation

(Roll to roll & within the same roll)

Definition:

Sometimes, there appears to be a difference in the

depth of shade, between the roll to roll & from place to place, in the same

roll. The defect will show up clearly, in the garments, manufactured from such

fabric.

Causes:

- Shade variation can be as a result of mixing of

the, fabrics of two different lots.

- Shade variation is also caused, by the

variation in the process parameters i.e. Time, Temperature & Speed

etc. from one fabric roll, to the other.

- Shade variation can appear to be, in fabrics

with GSM variation, caused due to the uneven stretching, unequal fabric

overfeed % etc.

Remedies:

- Ensure that the grey fabric used for one shade,

is knitted from the same lot of the yarn.

- Ensure that the same process parameters (Width,

Overfeed, Temperature & Machine Speed etc.) are used, for each roll of

a dye lot.

Tonal variation

Definition:

Roll to roll or within the same roll difference in

the color perception i.e. Greenish, Bluish, Reddish or Yellowish etc., is

attributed as tonal variation in the shade.

Causes:

- (Wrong leveling agent selection or wrong dyes

combinations)

- (Impurities like, Oil & Wax etc. not being

completely removed in Scouring)

- Level dyeing not being done, due to the inappropriate

leveling agents.

- Variation in the process parameters, e.g.

Temperature, Time & Speed etc

- (Tonal variation in the fabric is caused, due

to the variations, in the fabric processing parameters i.e. Temperature,

Time & Speed etc. of the Shrink Dryer & Stenter, especially if,

the machine is repeatedly stopped.)

Remedies:

- Use appropriate leveling agents, to ensure

uniform & level dyeing.

- Scour the grey fabric thoroughly, to ensure the

removal of all the impurities.

- Ensure that the whole lot of the dyed fabric is

processed, under uniform process parameters.

Wet Squeezer Marks

Definition:

The fabric on the edges of the fabric tube gets,

permanent pressure marks, due to the, hard pressing by the squeezer rolls. These

marks appear as distinct lines, along the length of the fabric & can’t be

corrected.

Causes:

- These marks are caused due to the excessive

pressure, of the squeezer rolls of the Padding Mangle, on the wet fabric,

while rinsing.

Remedies:

- Use the Padding mangle, only for the

application of the softener.

- Use a hydro extractor (Centrifuge) for the

extraction, to avoid the squeezer roll marks.

- Soon after extraction, open the fabric

manually, to prevent crease marks in the damp fabric.

Folding Marks

Definition:

Fold marks appear as distinct pressure marks, along

the length of the fabric

Causes:

- High pressure of the fabric Take Down rollers

of the Knitting machine, on the grey fabric, is one of the main causes.

- Too much pressure of the feeding rolls of the

Calander & Compactor is, the primary cause of the folding marks, in

the knitted fabric.

Remedies:

- Adjust the gap between the two rolls, as per

the thickness of the fabric sheet (Pique, S.J. etc.)

- Gap between the two

Calander rolls should be just enough, to let the rolls remove, the wrinkles in the fabric, but

put no pressure on the fabric sheet, especially in the case of Pique &

structured fabrics.

Crease Marks

Definition:

Crease marks appear in the knitted fabric, as dark haphazard

broken or continuous lines.

Causes:

- Damp fabric moving at high speed in twisted

form, in the Hydro extractor (Centrifuge)

Remedies:

- Use anti Crease, during the Scouring & the

Dyeing process

- (The use of anti Crease, swells the Cellulose

& prevents the formation of Crease marks)

- Spread the fabric in loose & open form

& not in the rope form, in the Hydro Extractor.

Skewing or Diagonal Grain Lines (Wales)

Definition:

Fabric Wales appear in the diagonal direction, to

the edges of the fabric, instead of being parallel.

Causes:

- Improper feeding of the fabric, while

Calandering & Compacting.

Remedies:

- Keep a slit line on one side of the tubular

fabric.

- Use the slit line, as a reference line, to keep

the grain lines straight, while feeding the fabric slowly, on the

Calander, or the Compactor machines.

High Shrinkage

Definition:

The original intended measurements of the Garment

go, haywire, during storage or after the very first wash.

Causes:

- High Stresses & strains exerted on the

fabric, during Knitting, Dyeing & Processing & the fabric not

being allowed to relax properly, thereafter.

- (High shrinkage is primarily due to the fabric

being subject to high tension, during the Knitting, Dyeing & the

Finishing processes)

Remedies:

- Keep the Grey Fabric in loose plated form,

immediately after the roll is cut.

- Store the finished fabric also in the plated

form & not in the roll form.

- Allow the fabric to relax properly, before it

is cut.

- Give maximum overfeed to the fabric, during the

processing, on the Stenter, Compactor & the Calandering machines.

GSM Variation

Definition:

The fabric will appear to have a visible variation

in the density, from roll to roll or within the same roll of, the same dye lot.

Causes:

- Roll to roll variation in the, process

parameters, of the fabric, like; Overfeed & Widthwise stretching of

the dyed fabric, on the Stenter, Calander & Compactor machines.

- Roll to roll variation in the fabric stitch

length.

Remedies:

- Make sure that all the fabric rolls in a lot,

are processed under the same process parameters.

- The Knitting Machine settings, like; the

Quality Pulley diameter etc. should never be disturbed.

Fabric Width Variation

Definition:

Different rolls of the same fabric lot, having

difference in the finished width of the fabric.

Causes:

- Grey fabric of the same lot, knitted on

different makes of Knitting Machines, having varying number of Needles in

the Cylinder.

- Roll to roll difference, in the Dyed Fabric

stretched width, while feeding the fabric on the Stenter, Calander &

Compactor.

Remedies:

- THE WHOLE LOT OF THE GREY FABRIC SHOULD BE KNITTED ON THE SAME

MAKE OF KNITTING MACHINES.

- FOR THE SAME GAUGE

& DIAMETER OF THE KNITTING MACHINES, THERE CAN BE A DIFFERENCE OF AS

HIGH AS 40 NEEDLES, FROM ONE MAKE TO THE OTHER MAKE OF THE MACHINE.

- THIS DIFFERENCE, IN

THE NUMBER OF NEEDLES, CAUSES A DIFFERENCE OF UPTO 2”- 3” IN THE FINISHED

WIDTH OF THE FABRIC.

- THE STRETCHED WIDTH OF THE GREY FABRIC SHOULD REMAIN

CONSTANT, DURING FINISHING ON THE STENTER.

Problems faced in Knits on the Cutting Table

(Curling of the Single Jersey Fabrics)

Definition:

Single Jersey

fabrics, when layered on the cutting table tend to, curl at the edges.

Causes:

- Dimensional instability of the Single Jersey

knitted fabrics

- The face side of the fabric has loops, whereas

the back side has only yarn floats. So, there is an imbalance, between the

face & the back side of the fabric.

Remedies:

- Gumming on both the edges of the S.J. fabrics,

while Stentering, can control the curling.

Measurement Problems

Definition:

The measurements of the garments totally change

after, a few hours of relaxation & after the first wash. The arm lengths or

the front & back lengths of the garments may vary, due to the mix up of the

parts.

Causes:

- Shrinkage caused due to the inadequate

relaxation of the knitted fabrics, before cutting.

- Mixing of the garment parts cut from, different

layers or different rolls of the knitted fabric.

Remedies:

- Use a trolley, for laying the fabric on the

table, to facilitate a tension free, laying.

- Let the fabric relax for a few hours, before

cutting, especially the Lycra fabrics.

- Ensure

the numbering of the different layers of the fabric, to prevent the mix up

of the components.