Stripping:

Stripping is carried out to remove uneven of shade or to reduce darkness of shade.

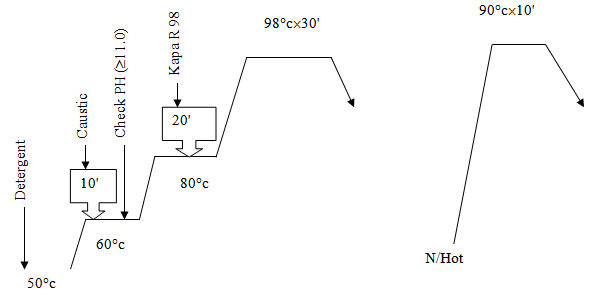

Full stripping for 100% cotton:

- Detergent: 1 g/l

- Caustic soda: 3 g/l

- Kapatex R 98: 5g/l

Process steps:

- Take water at required level

- Load the fabric

- Raise the temp at 60 Degree C & circulate the fabric..

- Add sequestering agent, anticreasing agent..

- Raise the temp. at 70 Degree C add Castic soda..

- Raise the temp. at 80 Degree C & add Hydrose..

- Circulate the fabric & raise the temp at 100 Degree C & continue 60 min

- Decrease the temp at 80 Degree C & rinse for 10 min & drain

- Add acetic acid and raise the temp. . at 60 Degree C and run for 10 min..

- Drain

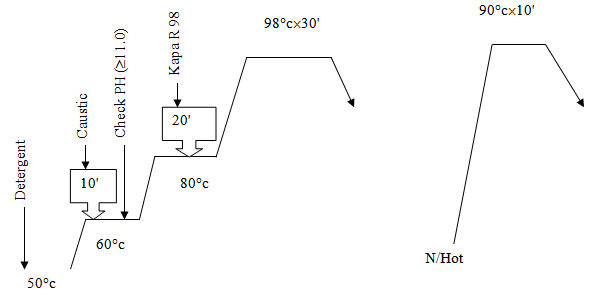

Washing for colored fabrics:

- The colored fabrics to be washed is loaded in the machine

- Required amount of water is taken

- PCLF (detergents) added & washing continued at 80 Degree C for 20 mins

- Cold washing

Re-dyeing:

When shade is not matched then fabric is treated again in dyeing machine for shade matching is known as re-dyeing..

Generally, re-dyeing is done if the shade is deeper than the target shade. It may occur when the fabrics absorb one or two colors more or less.

Generally, re-dyeing is done if the shade is deeper than the target shade. It may occur when the fabrics absorb one or two colors more or less.

One re-dyeing process is described below..

- Drain the let off solution

- Hot wash at 70-80 Degree C

- Acid wash at 60-70 Degree C(60 for light shade & 70 Degree C for deep shade)..

- Soda ash washes at 90-100 Degree C for 60 mins to reduce the depth of shade..

- Acid wash at 60 Degree C..

- Addition to required dyestuffs..

- Salt addition..

- Soda ash addition..

No comments:

Post a Comment